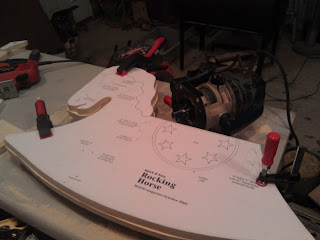

Last week I mentioned that I had bust sanding the rocking horse parts, well I am proud to say that the rocking horses are done.

Over the weekend I started finishing, the saddle parts all got a coat of stain.

I was trying to finish the rocking horse using the same technique that I had watched Marc (The Wood Whisperer) use which was to give the sides a coat of shellac before staining the mane. Below are the all the parts that got a spray coat of Clear Zinsser Bulls Eye Shellac.

However when I tried to stain the mane area the shellac kept the wood from taking any stain, so I sanded the shellac off the area to be stained. and here it how the mane looked after wards.

The next day after the stain had time to dry/cure I brushed on 2 coats of shellac. Shellac dries and can be recoated in around a hour.

Once everything had a chance to dry it was time assemble the rocking horses.

I used a plug cutter to plug the screw holes on the sides. The plugs were then trimmed and sanded flush. Then the sanded area was touched up with a light coat of shellac.

After assembly the rocking horses got 2 more coats of shellac sprayed on.

I think I am more excited about these presents than any present ever. One is for my son who is almost 1.5 and the other is for my nephew. I can't wait to see the boy's reaction to them.

Merry Christmas and may God bless you and yours.

After I cut the tails I traced the tail locations onto the other piece to make the pins. I didn't have a good way to hold the pieces together while doing this which i think was a major source of error, not to mention my inability to saw where I needed to. The joint did go together with a little persuasion, but doesn't fit together nicely. But I did succeed in making a set of hand cut dovetails.

After I cut the tails I traced the tail locations onto the other piece to make the pins. I didn't have a good way to hold the pieces together while doing this which i think was a major source of error, not to mention my inability to saw where I needed to. The joint did go together with a little persuasion, but doesn't fit together nicely. But I did succeed in making a set of hand cut dovetails.

Now I had a apple blank that was roughly 2" thick and 8" long and 3" wide. I knew I wanted to make a bandsaw box but had to stew about what shape to make it and where to go from there. I ended up making a oval shaped box. I will do a how to write up next time I make a bandsaw box. I applied several coats of boiled linseed oil to the box before putting 4 coats of spray on poly on it. For my first attempt at a box I am happy with how it turned out.

Now I had a apple blank that was roughly 2" thick and 8" long and 3" wide. I knew I wanted to make a bandsaw box but had to stew about what shape to make it and where to go from there. I ended up making a oval shaped box. I will do a how to write up next time I make a bandsaw box. I applied several coats of boiled linseed oil to the box before putting 4 coats of spray on poly on it. For my first attempt at a box I am happy with how it turned out.